Refrigeration/Glycol

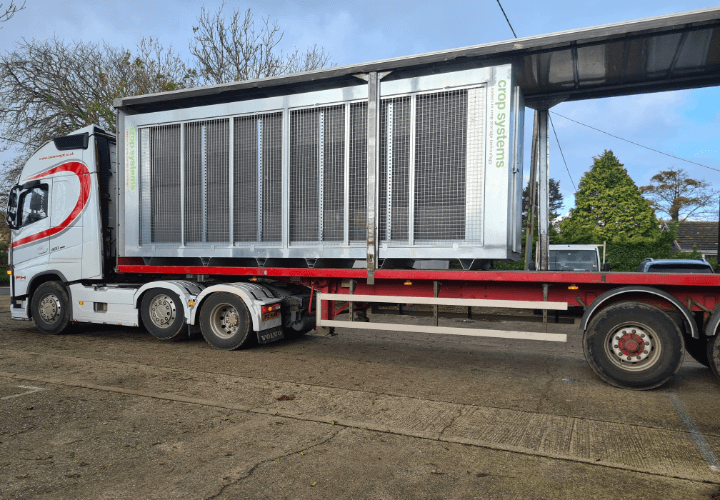

Crop Systems Ltd uses the most modern compressors, inverters and controllers to enable customers to store crops for as long as they need at minimal financial and environmental cost.

We also use glycol as a coolant because – in a typical 150kW store – you will need less than 40 kg of refrigerant, compared to 150 – 180 kg of conventional refrigerants, which reduces set up and running costs, and also reduces leakage risks, which reduces your store’s global warming potential. In addition, the coils don’t need to be de-frosted so frequently.

We use glycol as a refrigerant medium because it is more efficient than the alternative DX system. Our system uses a quarter of the volume of refrigerant gas, which drastically cuts maintenance costs.

Our systems combine large surface area coils with high airflows to achieve optimum performance and virtually eliminate de-frosting, greatly reducing operational costs.

Users can monitor and manage all parts of the system via our SmartStorTM controller, which gives you full remote control of your system no matter where you are.

SmartStor™ / SmartSola™

Store controller

SmartStor™ / SmartSola™ enables owners to monitor and manage their facilities on their mobile device from anywhere.

TaperStor™

Bulk store

TaperStor™ uses tapering ducts throughout the store to maintain even airflow throughout the store.

WarmStor™

Conditioning store

WarmStor™ is an innovative box store than enables potatoes to be warmed gently prior to processing.

PosiStor™

Box store

PosiStor™ uses positive ventilation to ensure box stores are both effective in storing potatoes and economic to run.

CoolStor™

Refrigeration

Crop Systems Ltd manufactures top quality refrigeration systems that optimise efficiency and minimise costs.