WarmStor™

WARMSTOR ™ is an innovative design of box store that uses a low energy Air Source system to gently warm potatoes, so store operators can present their customers with potatoes in the ideal condition for processing.

It uses low-grade heat from ambient air to achieve a gentle warming process that avoids both the potential damage to the crop such as ‘thumb-nailing’, and the high bills that can result from using gas or kerosene burners.

An innovative control system can enable potatoes at different temperatures to be successfully stored and prepared for load out alongside each other.

Existing users report huge reductions in energy bills, and that staff find the system incredibly easy to manage.

SmartStor™ / SmartSola™

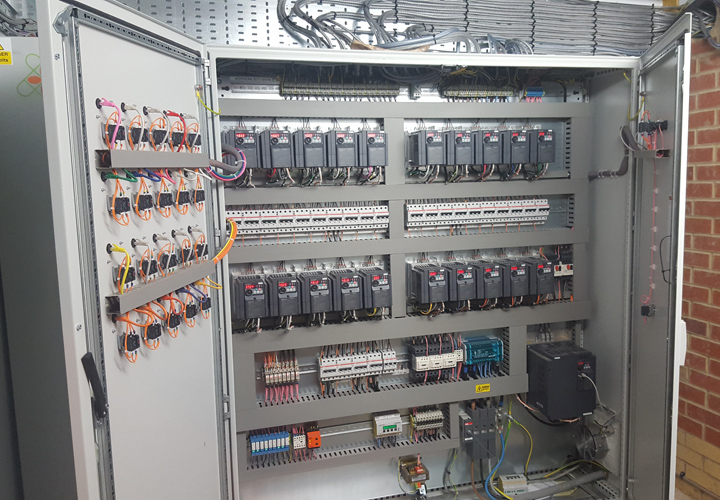

Store controller

SmartStor™ / SmartSola™ enables owners to monitor and manage their facilities on their mobile device from anywhere.

TaperStor™

Bulk store

TaperStor™ uses tapering ducts throughout the store to maintain even airflow throughout the store.

WarmStor™

Conditioning store

WarmStor™ is an innovative box store than enables potatoes to be warmed gently prior to processing.

PosiStor™

Box store

PosiStor™ uses positive ventilation to ensure box stores are both effective in storing potatoes and economic to run.

CoolStor™

Refrigeration

Crop Systems Ltd manufactures top quality refrigeration systems that optimise efficiency and minimise costs.